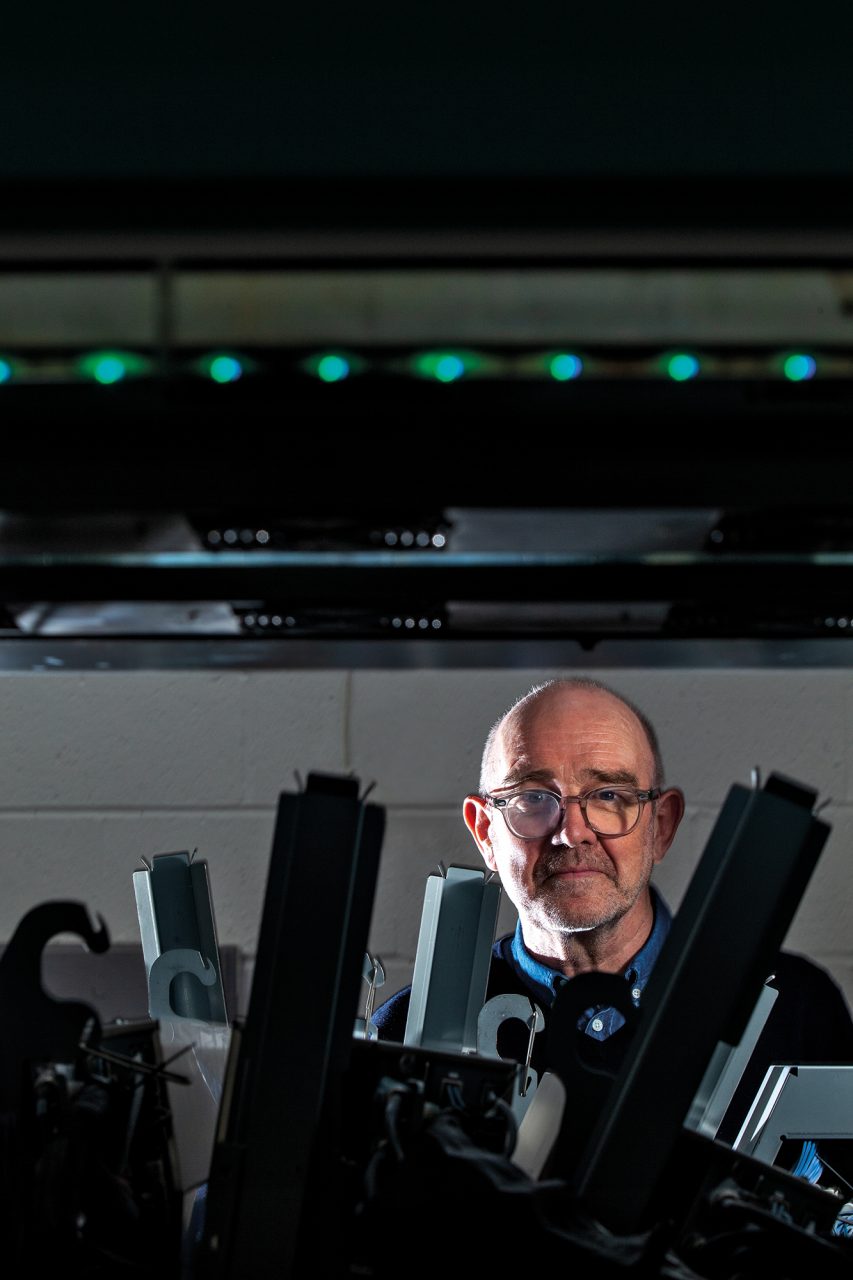

Fujifilm product manager Mark Stephenson highlights the advantages of digital for the circular economy for anyone concerned about the environmental impact of the print chain. ‘There are a low number of consumables compared to offset, no waste plates and blankets.’ He cheerfully points to de-inkability as one of the Jet Press’s advantages over its digital rivals, since it is more difficult to de-ink toner and electro-ink.

Customisation

Personalisation is a feature of digital printing that has implications for both sustainability and creativity. It chimes with the evolving demands and aspirations of consumers for less waste and more special and unique artefacts, a feelgood combination of ‘we’ and ‘me’.

Peled Vaissman writes that variable data printing allows designers ‘to use information the consumer has given us to make it the most relevant product possible for them.’ HP’s Industrial Marketing Manager Dana Craciun notes the way customers increasingly seek work that is premium and customised, writing that HP Indigo ‘gives printers the flexibility to meet all of these needs efficiently.’ Ricoh’s Campbell sees variable data as a way to respond to current changes in consumption: ‘The pandemic may hasten the change or become a tipping point,’ he notes. ‘Brands need to establish trust, and personalisation is key.’

Creative director Silas Amos has no illusions about the challenges of explaining variable data projects to clients, and the need to find someone brave enough to try something new: ‘The ideal candidate is someone young enough to want to make their reputation, but senior enough to make their own decisions!’

Push’s Killen points out that the arts and cultural sector is getting more targeted, with ‘a strong, evolving niche in the market … jobs where there are only 100 copies but it has to look beautiful, with exposed binding and so on.’ Pureprint’s Owers says: ‘Now that we can vary the content of each copy on the run there are often very short runs at a price point that would have been impossible a few years ago.’ Yet variable data is not just about small print runs – Peled Vaissman has overseen packaging projects for clients such as Coca-Cola that run into millions, with every item different. Berresford picks up the thread. ‘We have just achieved a record number of orders in the last 24 hours. A lot of lay-flat books that look absolutely stunning. Nice thick pages that look gorgeous.’ However the ‘targeted’ nature of these products means that less adventurous clients know nothing about them.

The digitally printed projects shown in this edition of Pulp are just a small selection from the rapidly evolving digital printing universe, chosen to show a wide variety of inspiring approaches from ambitious makers, publishers and designers.